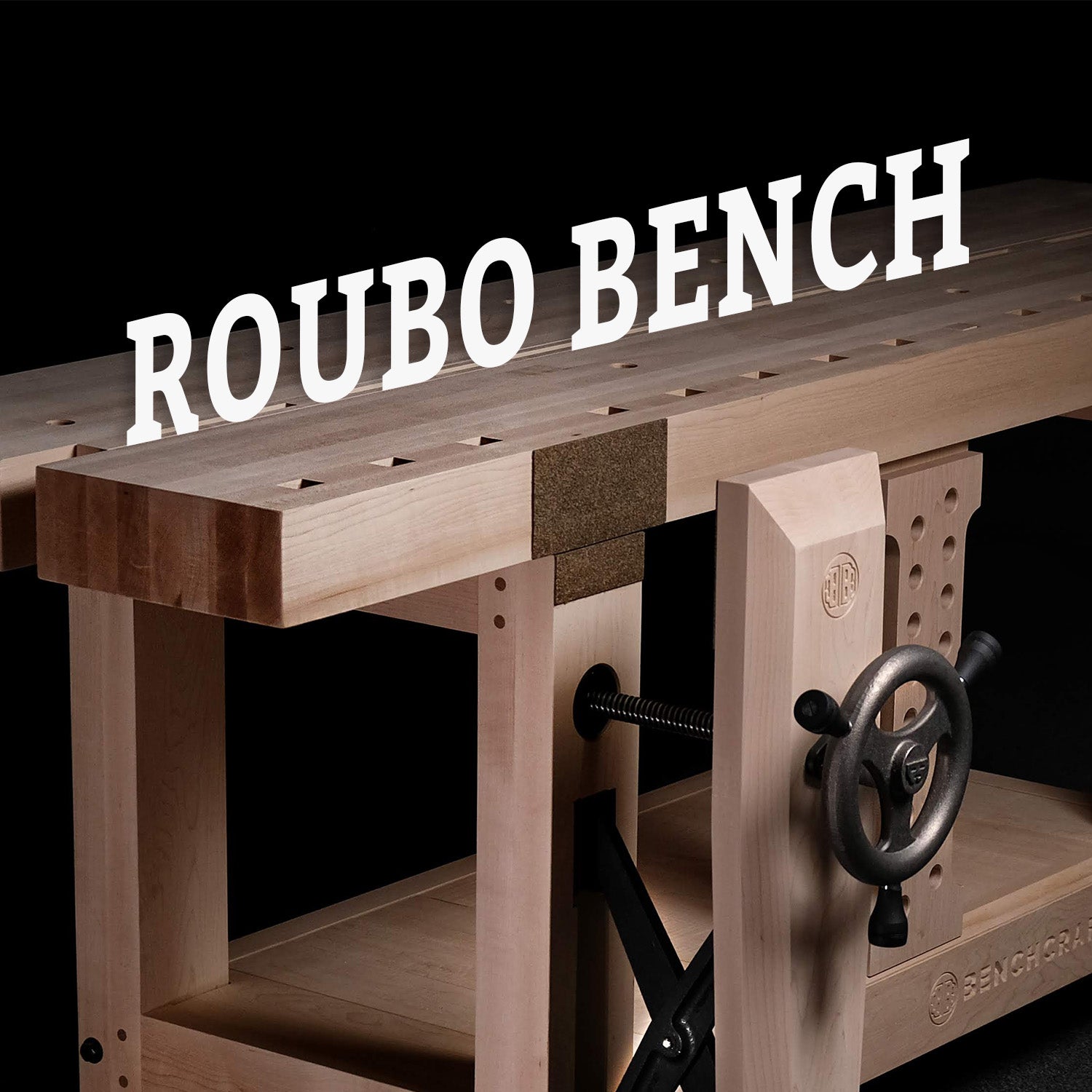

Moxon

Our Moxon vise is the twin screw vise that offers excellent grip with quick release and adjustment. It's perfect for working the ends of boards, dovetails, and wide pieces.

Complete Moxon Vise: comes in hard maple and is ready to use in just a few minutes. The wood components are milled and completely prepared for you to install the hardware into, then glue on the included Crubber. Wood is provided in the white (no finish applied). See instructions for further details.

The Benchcrafted Moxon Vise mounts to any workbench, raising your workpiece to a comfortable, ergonomic position and holding it rock solid. If you cut dovetails or other joints by hand, a Moxon vise will completely change your experience with these tasks. No longer do you need to strain your back when cutting dovetails at the lower height of your main bench. Fast and effortless, the Moxon vise makes joinery a pleasure.

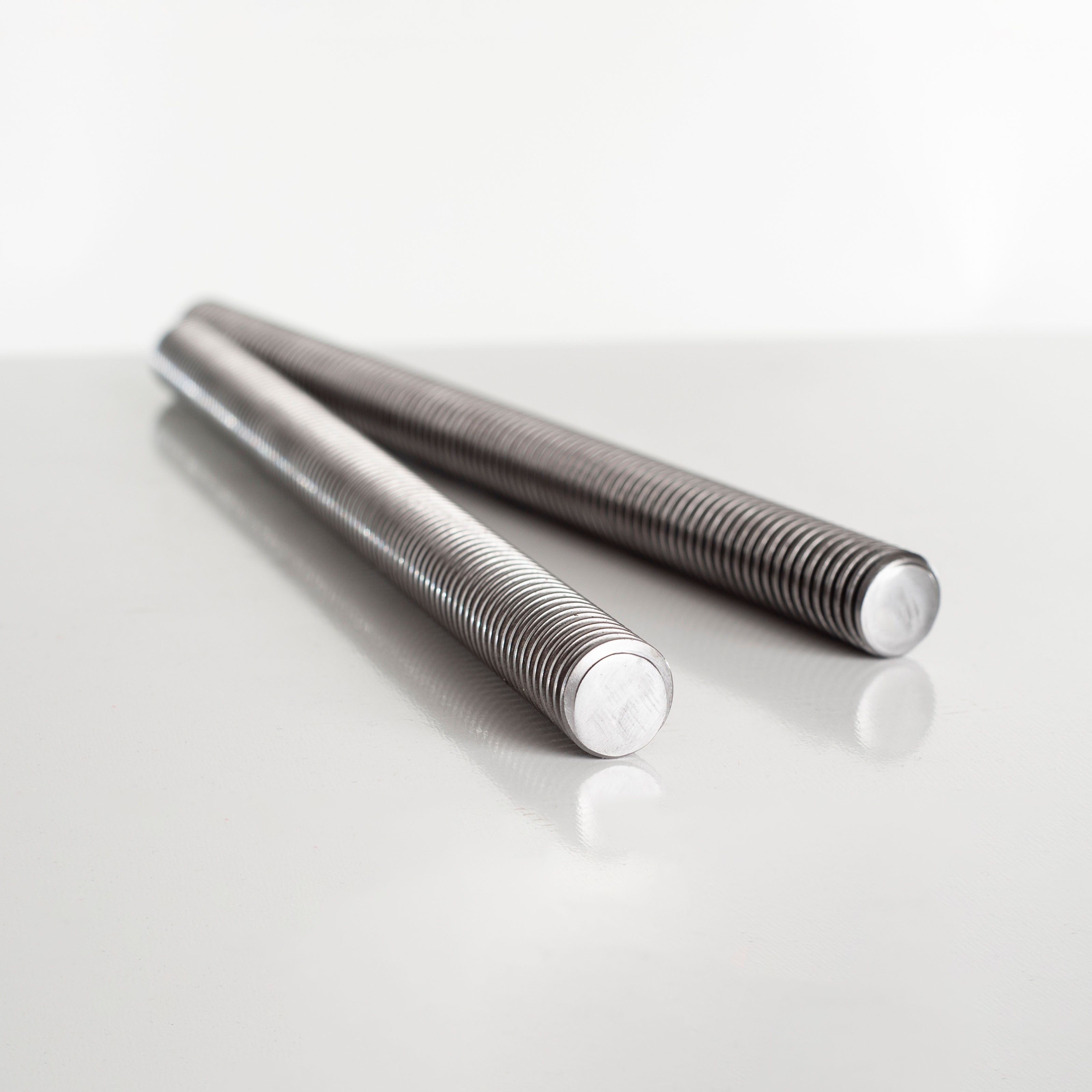

The Moxon hardware uses the same precision rolled acme screws as our other vises. Like those vises, we’ve outfitted our Moxon vise with cast iron hand wheels for rapid, easy adjustment. However, we’ve changed things around a bit. Instead of the handwheel rotating the screws and being restricted by the weight of the movable jaw, we’ve fixed the screws to the vise itself (they don’t move) and tapped the handwheels, allowing them to spin in and out on the rigid screws. The mass of the wheels and the polished acme threads allows the handwheels to spin freely and do the work of drawing the jaws together effortlessly.

Mounting

The vise mounts to any bench with holdfasts, between dogs, or held down by clamps. The rear stabilizer prevents the vise from vibrating under sawing forces, and provides a place to clamp the vise to your bench. The front, movable jaw hangs down a little lower than the rear, so when you set the vise onto your bench, the front jaw provides a stop for accurately positioning the vise onto the bench. The rear jaw's inside face automatically ends up flush with the front edge of your bench.

Grip

The movable jaw is lined with Crubber for a tenacious grip, so you don't have to crank down on the handwheels to hold your work.

Operation

Operating the vise is easy. Setting one wheel for the workpiece thickness, the opposite wheel is massive enough to literally push the jaw to the workpiece and hold it there solidly with only a quick spin of the wheel. In most cases, that's all that’s necessary to hold the work. To remove the workpiece, simply loosen one handwheel and lift the workpiece out. Pulling back on the front jaw with the workpiece releases it.

Capacity

The jaws will open to a maximum of about 2 1/4". More than enough for this vise's purpose. You can build the vise to any width you choose. Many of our customers build two Moxon vises, using two sets of hardware. One with a smaller capacity, around 16" which is used for smaller chests and drawer sides. And one with 24" capacity between screws for full size chests and cabinet work. The smaller vise is lighter and easier to mount and store for these more frequent projects. Elongated holes in the movable chop allow the vise to hold tapered pieces with ease.

Versatility

The Moxon hardware can be used to build a "bench on bench" Moxon vise. A work surface is added to the rear jaw to act as a separate bench top. It's the ideal bench accessory for cutting and marking out dovetails with its large work surface.

Another option is to permanently build a full-size Moxon into a dedicated joinery bench, which is taller than your main workbench. This eliminates the need to mount or store the vise. Generally, the height of the bench top should be about 4" below your elbow with your arm bent at 90 degrees.

Video

Specifications

Cast and machined from steel components

Designed and made in the USA

Two 5" cast iron handwheels, sand-mold finish - Acme-thread tapped

Two 5" cast iron handwheels, fully machined finish - Acme-thread tapped

| All Models |

Two 8" precision rolled carbon steel acme screws with four acme nuts and thick washers

| All Models |

Crubber jaw liner for a tenacious, non-marring grip

All hardware needed to build the vise

Installation Instructions

Installation instructions for all our products are supplied only in PDF format. Please download and review the instructions before using your product.

Similar Products